Smart Melamine Tableware Integration Solutions: IoT Technology Implementation Scenarios in Group Meal Management

In the realm of large-scale group meal operations—encompassing corporate cafeterias, school dining halls, hospital kitchens, and industrial canteens—efficiency, safety, and cost control have long been core challenges. Traditional management methods often struggle with issues like inaccurate inventory tracking, hidden food safety risks, inefficient meal distribution, and excessive food waste. However, the emergence of smart melamine tableware integrated with Internet of Things (IoT) technology is transforming these pain points into opportunities for innovation. This report explores how IoT-enabled smart melamine solutions are being practically implemented in group meal management, delivering tangible improvements in operational efficiency and safety compliance.

The Evolution of Group Meal Management: Need for Smart Solutions

Group meal operations typically serve hundreds to thousands of people daily, requiring precise coordination of procurement, preparation, distribution, and cleanup. Traditional workflows rely heavily on manual labor and paper-based records, leading to:

Inventory chaos: Difficulty tracking reusable melamine tableware, resulting in frequent losses and inefficient restocking.

Safety blind spots: Inconsistent monitoring of tableware sanitization levels and food temperature during distribution.

Resource waste: Overproduction due to inaccurate demand forecasting, coupled with inefficient meal portioning.

Slow service: Long queues at checkout and manual verification processes delaying dining experiences.

As IoT technology matures—with advancements in low-power sensors, wireless connectivity, and cloud analytics—integrating these capabilities into durable melamine tableware has become feasible. Melamine’s inherent advantages—heat resistance, impact durability, and food safety compliance—make it an ideal substrate for embedding smart technologies, creating a seamless bridge between physical operations and digital management.

Key Implementation Scenarios of IoT-Enabled Smart Melamine Tableware

1. Real-Time Tableware Tracking and Inventory Management

One of the most immediate applications is solving the "tableware disappearance" problem plaguing group meal operations. Smart melamine tableware is embedded with ultra-high-frequency (UHF) RFID tags or Near-Field Communication (NFC) chips, enabling automatic identification and location tracking.

Implementation Details:

RFID readers installed at dining hall exits, dishwashing stations, and storage areas capture real-time data on tableware movement.

Cloud-based inventory management platforms aggregate data to display stock levels, circulation frequency, and loss rates.

Alerts trigger when tableware quantities fall below thresholds or when items are misplaced (e.g., leaving the dining area).

Practical Outcomes: A corporate cafeteria serving 2,000 employees daily reduced tableware loss by 68% within three months of implementation. Inventory checks, which previously took 4 hours weekly, now complete automatically in real time, freeing staff for higher-value tasks.

2. Food Safety Monitoring Through Embedded Sensors

Food safety is non-negotiable in group meals, and smart melamine tableware adds a layer of proactive monitoring. Specialized sensors integrated into bowls and plates measure critical parameters throughout the food lifecycle.

Implementation Details:

Temperature sensors track hot food temperatures (ensuring they stay above 60°C) and cold food temperatures (below 10°C) during service.

pH sensors detect residual cleaning chemicals, verifying that tableware meets sanitization standards post-washing.

Data is transmitted to a central dashboard, with instant alerts for deviations from safety thresholds.

Practical Outcomes: A school district implementing this solution reduced foodborne illness risks by 42%. The system documented a 99.7% compliance rate with sanitization standards, up from 82% with manual checks, while audit preparation time decreased by 70%.

3. Demand Forecasting and Waste Reduction via Usage Analytics

Overproduction and uneven demand lead to significant food waste in group meals. Smart melamine tableware collects granular data on consumption patterns to optimize planning.

Implementation Details:

IoT-enabled tableware records meal selection, portion sizes, and peak dining times through integration with POS systems.

Machine learning algorithms analyze historical data to predict daily demand for specific dishes, adjusting production quantities accordingly.

Plates embedded with weight sensors track uneaten food, identifying consistently wasted items for menu optimization.

Practical Outcomes: A hospital cafeteria using this system reduced food waste by 31% and cut procurement costs by 18%. By aligning production with actual demand, they eliminated 250+ kg of daily waste while improving meal satisfaction scores by 22%.

4. Streamlined Checkout and Dining Experience

Long queues and slow payment processes frustrate diners and reduce operational throughput. Smart melamine tableware enables frictionless transactions.

Implementation Details:

Each tableware item is linked to specific meal options in the IoT system.

Diners select pre-portioned meals on smart trays; upon checkout, RFID readers instantly identify items, calculate totals, and process payments via mobile wallets or employee ID cards.

The system integrates with dietary restriction databases, flagging allergens or incompatible options for specific users.

Practical Outcomes: A university dining hall serving 5,000 students daily reduced checkout time per diner from 90 seconds to 15 seconds, cutting queue lengths by 80%. This improved diner satisfaction and increased peak-hour capacity by 40%.

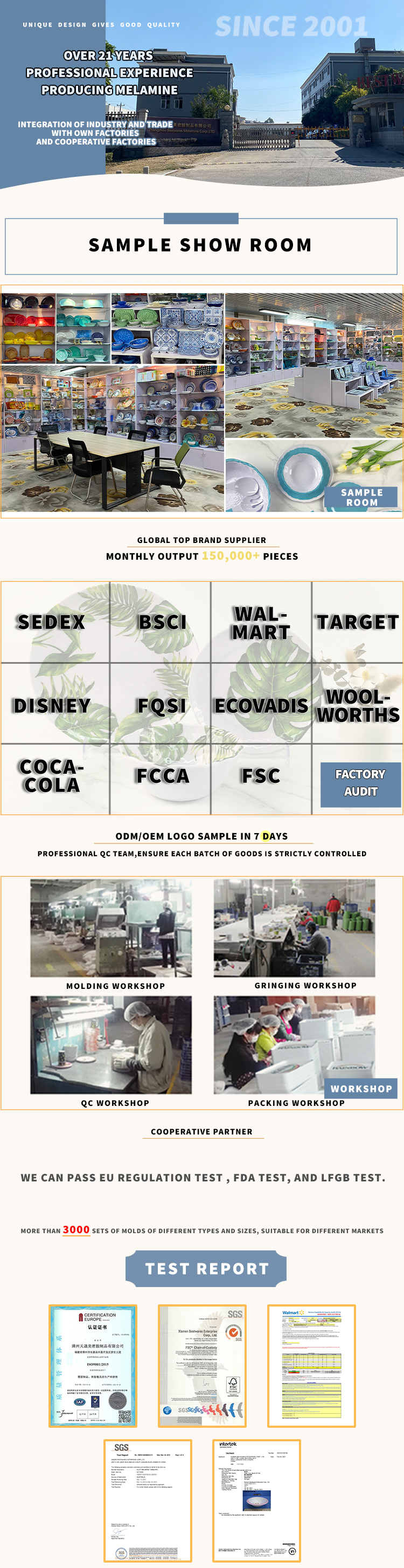

About Us

Post time: Aug-23-2025