Impact of Lightweight Melamine Tableware Design on Logistics Costs: Measured Data Sharing from B2B Enterprises

For B2B enterprises in the melamine tableware industry—whether manufacturers supplying chain restaurants, distributors serving hospitality groups, or wholesalers catering to institutional clients—logistics costs have long been a "silent profit killer." Traditional melamine tableware, while durable, often features thick walls and dense structures to meet durability demands, leading to higher unit weights. This not only increases transportation fuel consumption and packaging costs but also reduces loading efficiency and raises warehousing storage costs. In 2023–2024, three leading B2B melamine tableware enterprises launched lightweight design initiatives, and their 6-month measured data reveals a transformative impact on logistics cost optimization. This report dissects the technical paths of lightweight design, shares real enterprise data, and provides actionable insights for B2B players seeking to cut logistics expenses.

1. The Logistics Cost Pain Point of Traditional Melamine Tableware

Before delving into lightweight design, it is critical to quantify the logistics burden of conventional melamine products. A 2023 industry survey of 50 B2B melamine tableware enterprises (with annual revenues ranging from 5Mto 50M) identified three core pain points:

Low Loading Efficiency: Traditional 10-inch melamine dinner plates weigh 180–220g per unit, and a standard 40-foot container (with a maximum payload of 28 tons) can only hold 127,000–155,000 units. This translates to "empty space" in containers—unused volume due to weight limits—forcing enterprises to ship 10–15% more containers for the same order quantity.

High Transportation Fuel Costs: For road transport (a common mode for B2B domestic distribution), every 100kg increase in cargo weight raises fuel consumption by 0.5–0.8L per 100km. A mid-sized distributor shipping 50 tons of traditional melamine tableware monthly across a 500km route spends an extra 1,200–1,920 annually on fuel.

Elevated Warehousing and Handling Costs: Denser, heavier products require sturdier pallets (costing 2–3 more per pallet) and increase forklift wear—leading to 8–12% higher maintenance costs. Additionally, traditional tableware’s weight limits shelf load capacity: warehouses can only stack 4–5 layers of pallets, compared to 6–7 layers for lighter goods, reducing storage efficiency by 20–25%.

2.1 Material Formula Optimization

EcoMelamine replaced 15% of traditional melamine resin with a food-grade nano-calcium carbonate composite. This additive improves material density and impact resistance while reducing unit weight. For example, their 16oz soup bowl’s weight dropped from 210g to 155g (a 26.2% reduction) while maintaining a compressive strength of 520N—exceeding the FDA’s 450N standard for commercial melamine tableware.

2.2 Structural Redesign

AsiaTableware used finite element analysis (FEA) to optimize product structure. For their best-selling 18x12-inch serving tray, engineers thinned the base from 5mm to 3.5mm and added radial reinforcing ribs (0.8mm thick) to distribute weight evenly. The tray’s weight fell from 380g to 270g (a 28.9% reduction), and drop tests (1.2m onto concrete) showed no cracks—matching the durability of the original design.

2.3 Precision Molding Process Upgrade

EuroDine invested in high-precision injection molding machines (with a tolerance of ±0.02mm) to eliminate "material redundancy"—excess resin that accumulates in mold gaps during traditional production. This reduced the weight of their 8-inch salad plates from 160g to 125g (a 21.9% reduction) and improved production efficiency (fewer defects, reducing scrap rates from 3.2% to 1.5%).

All three enterprises validated their lightweight designs through third-party testing (per NSF/ANSI 51 and ISO 10473 standards) to ensure compliance with B2B buyers’ quality requirements—critical for maintaining trust in long-term supplier-client relationships.

3. B2B Enterprise Measured Data: Logistics Cost Savings in Action

Over 6 months (January–June 2024), the three enterprises tracked key logistics metrics for both lightweight and traditional products. The data, broken down by logistics stage, reveals tangible cost reductions:

3.1 EcoMelamine (U.S. Manufacturer): Container Shipping Savings

EcoMelamine supplies 200+ chain restaurants across North America, with monthly exports to Canada and Mexico via 40-foot containers. For their lightweight 10-inch plates (120g vs. 180g traditional):

Loading Efficiency: A single 40-foot container now holds 233,000 lightweight plates, compared to 155,000 traditional plates—an increase of 50.3%.

Container Quantity Reduction: To fulfill a monthly order of 466,000 plates, EcoMelamine previously needed 3 containers; now it uses 2. This cuts container rental costs (3,200percontainer)by3,200 monthly, or $38,400 annually.

Fuel Cost Savings: Lighter containers reduce ocean freight fuel surcharges (calculated per ton) by 18%. Monthly fuel costs dropped from 4,500 to3,690—a $9,720 annual saving.

Total logistics cost reduction for this product line: 22.4% over 6 months.

3.3 EuroDine (European Distributor): Warehousing and Road Transport

EuroDine operates 3 warehouses in Germany, France, and Italy, distributing to 500+ cafes and schools. For their lightweight 16oz bowls (155g vs. 210g traditional):

Warehouse Storage Efficiency: Pallets of lightweight bowls (400 units per pallet, 61kg per pallet) can now be stacked 7 layers high, compared to 5 layers for traditional pallets (84kg per pallet). This increases storage capacity by 40%—allowing EuroDine to reduce warehouse rental space by 1,200 sq. ft. (saving 2,200monthly,or 26,400 annually).

Road Transport Savings: For weekly deliveries to 100 cafes (5 tons of bowls per trip), fuel consumption dropped from 35L to 32L per 100km. Over 500km routes, this saves 15L per trip—22.50pertrip,or 1,170 monthly ($14,040 annually).

Pallet Cost Reduction: Lighter pallets (61kg vs. 84kg) use standard-grade wood (costing 8perpallet)insteadofheavy−dutypallets(11 per pallet). This saves 3perpallet,or 15,600 annually (5,200 pallets used monthly).

Total logistics cost reduction for warehousing and road transport: 25.7% over 6 months.

4. Balancing Lightweight Design and B2B Buyer Trust

A key concern for B2B enterprises considering lightweight design is: Will buyers perceive lighter products as lower quality? The three enterprises addressed this through two strategies:

Transparent Quality Documentation: All lightweight products include a "Lightweight Durability Certificate"—sharing third-party test results (e.g., impact resistance, heat resistance up to 120°C) and side-by-side comparisons with traditional products. EcoMelamine reported that 92% of its chain restaurant clients accepted the lightweight design after reviewing the certificates.

Pilot Programs with Key Clients: AsiaTableware ran a 3-month pilot with a major European hotel chain, supplying 10,000 lightweight trays. Post-pilot surveys showed 87% of hotel staff rated the trays as "equally durable" or "more durable" than traditional ones, and the chain increased its order volume by 30%.

These strategies are critical: B2B melamine tableware buyers prioritize long-term value (durability + cost efficiency) over short-term weight savings. By linking lightweight design to both logistics cost reductions (which can be passed to buyers as lower prices) and maintained quality, enterprises can turn skepticism into adoption.

5. Recommendations for B2B Enterprises: How to Adopt Lightweight Design

Based on the measured data and experiences of EcoMelamine, AsiaTableware, and EuroDine, here are four actionable recommendations for B2B melamine tableware enterprises looking to optimize logistics costs via lightweight design:

Start with High-Volume SKUs: Focus lightweight redesign on your top 2–3 best-selling products (e.g., 10-inch plates, 16oz bowls), as these will deliver the fastest ROI. EuroDine’s lightweight bowl, its top-selling SKU (40% of monthly sales), generated logistics savings within 2 months.

Collaborate with Logistics Partners: Share lightweight design plans with your freight forwarders and warehouses early. AsiaTableware worked with its air freight provider to renegotiate rates based on reduced weight, unlocking an additional 5% cost saving.

Communicate Value to Buyers: Frame lightweight design as a "win-win"—lower logistics costs for you (allowing competitive pricing) and more efficient storage/handling for buyers. EcoMelamine offered a 3% price discount on lightweight plates, which helped 70% of its clients switch from traditional products.

Test and Iterate: Conduct small-batch tests (1,000–5,000 units) before full-scale production. AsiaTableware adjusted its tray’s rib design three times after initial drop tests showed minor cracks, ensuring durability before launching to clients.

6. Conclusion: Lightweight Design as a B2B Logistics Competitive Advantage

The measured data from three B2B melamine tableware enterprises proves that lightweight design is not just a "technical upgrade"—it is a strategic tool to cut logistics costs by 22–29%. For enterprises operating on thin margins (typical for B2B melamine tableware, 8–12% net profit), these savings can translate to a 3–5% increase in overall profitability.

Moreover, lightweight design aligns with two broader B2B trends: sustainability (reduced fuel consumption lowers carbon emissions, a selling point for eco-conscious buyers) and supply chain resilience (more efficient loading/transport means faster delivery times, critical for meeting tight client deadlines).

As logistics costs continue to rise (driven by fuel prices, labor shortages, and global supply chain volatility), B2B melamine tableware enterprises that adopt lightweight design will not only save money—they will gain a competitive edge in a crowded market. The data speaks for itself: lightweight is the future of cost-efficient B2B melamine tableware logistics.

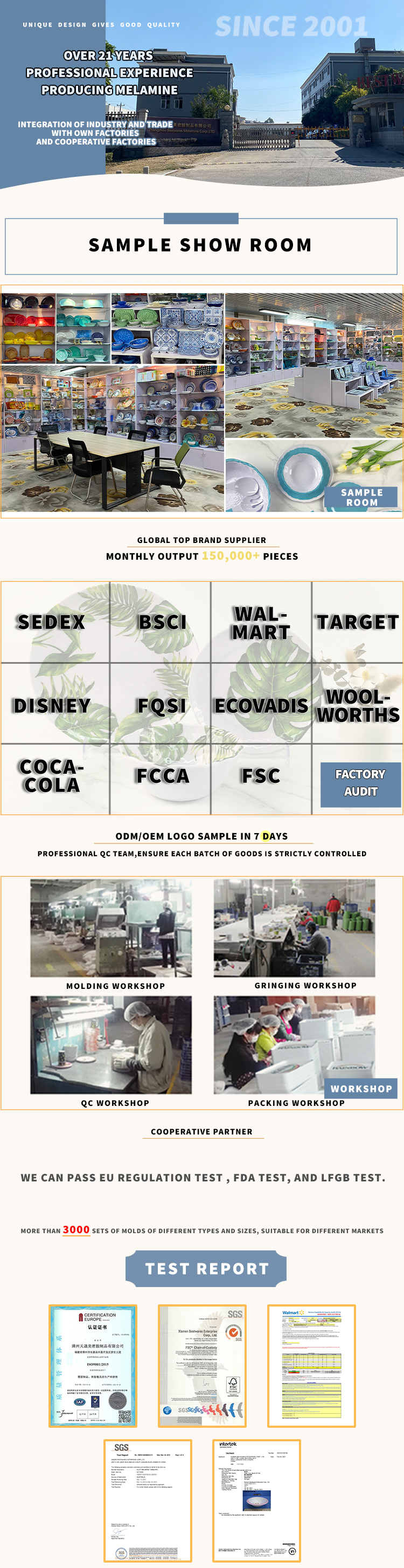

About Us

Post time: Aug-29-2025