Breakthrough in High-Temperature Resistant Melamine Tableware: Compatibility Test Report for Central Kitchen Equipment in Chain Restaurants

In chain restaurant operations, central kitchens ensure consistent quality and efficient distribution, but face a critical challenge: finding tableware that withstands high-temperature commercial equipment while maintaining compatibility with processing and sanitizing systems.

Traditional melamine tableware, valued for durability and affordability, fails above 120°C—problematic in central kitchens using high-temperature dishwashers, steam sterilizers, and ovens. This causes warping, discoloration, harmful substance release, safety risks, and high replacement costs.

The new tableware addresses these issues through modified materials and manufacturing, withstanding up to 180°C. Successful validation promises reduced costs, enhanced safety, improved efficiency, and streamlined processes by eliminating specialized tableware for different temperatures.

2. Test Standards, Samples, and Methodology

2.1 Test Standards

Testing followed international standards: ASTM C518-17, FDA 21 CFR Part 177.1460, ISO 22000, and NSF/ANSI 51, ensuring recognized, reliable results for temperature resistance, safety, and compatibility.

2.2 Test Samples

Samples included new high-temperature melamine items: 10-inch plates, 16 oz bowls, quart storage containers, 18x12-inch trays, and cutlery. Traditional melamine of identical specifications served as controls. All samples were new and unused.

2.3 Test Methodology

Conducted in a certified lab’s simulated central kitchen, tests used a phased approach for each equipment type. Samples underwent 12 cycles (each simulating one week of use) with evaluations for physical changes, chemical stability, functional integrity, and equipment compatibility.

3. Test Equipment and Results

3.1 Commercial Dishwashers

Operating at 60-71°C (washing) and 82-90°C (rinsing), samples endured 100 cycles in a Hobart AM15V dishwasher.

High-temperature melamine showed no warping, minimal scratching, no discoloration with tomato sauce/curry, and withstood 88°C rinsing. Traditional melamine had 30% warping after 50 cycles, significant discoloration by 30 cycles, and 15% cracking after 100 cycles.

3.2 Steam Sterilizers

Operating at 121-134°C under pressure, samples underwent 50 cycles in a Tuttnauer 2540E sterilizer (30 minutes at 121°C/15 psi).

High-temperature melamine showed no damage, stable weight, and no detectable melamine/formaldehyde leaching. Traditional melamine had severe warping after 10 cycles, 40% exceeding safe melamine levels by 5 cycles (80% by 20), and surface blistering/peeling.

3.3 High-Temperature Ovens

Samples endured 30 cycles (30 minutes at 180°C) in a Vulcan VC5GD oven.

High-temperature melamine showed no warping, cracking, or discoloration, with excellent thermal shock resistance and uniform heat distribution. Traditional melamine warped immediately, had 60% cracking after 5 cycles, and significant yellowing by 10 cycles.

3.4 Ultrasonic Cleaners

Samples underwent 50 cycles (15 minutes each) in a Branson CPX3800 cleaner.

High-temperature melamine showed no structural damage, intact surface finish, and no leaching. Traditional melamine had minor surface erosion on printed designs after 30 cycles and slight dulling.

4. Long-Term Durability and Safety

4.1 Long-Term Durability

After 6 months of simulated use (dishwashing, sterilization, and 95°C food contact), high-temperature melamine showed only minor scratching with intact structure and function. Traditional melamine had 70% unfit for use due to warping, cracking, or discoloration.

4.2 Safety Assessment

Migration tests with food simulants, heavy metal analysis, and formaldehyde/melamine release testing showed all levels below FDA/EU limits, confirming safety under rigorous conditions.

5. Practical Implications

5.1 Cost Savings

With 3-4x longer lifespan than traditional melamine, medium chains (50 locations) could save

50,000−100,000 annually. Compatibility reduces inventory costs by eliminating specialized tableware.

5.2 Operational Efficiency

Universal use from prep to serving eliminates food transfers, reducing time and contamination risks. Durability minimizes replacement downtime.

5.3 Food Safety & Brand Consistency

Stability prevents harmful releases during sanitization and reduces bacterial growth. Consistent appearance maintains brand image across locations.

6. Expert Opinions

Chef Maria Rodriguez noted: “These results are game-changing—tableware that works from dishwasher to sterilizer streamlines operations.” John Chen added: “Maintaining safety under extreme temperatures ensures standards while improving efficiency.” Dr. Emily Wong praised the “impressive formulation breakthrough with robust testing evidence.”

7. Conclusion and Outlook

Test results confirm the new melamine tableware withstands rigorous commercial conditions while maintaining safety and performance. Benefits include reduced costs, improved efficiency, enhanced safety, and brand consistency.

Future plans include expanding product range and ongoing real-world durability testing. This innovation sets new standards for foodservice tableware, offering chain restaurants a competitive edge through better efficiency, lower costs, and enhanced safety.

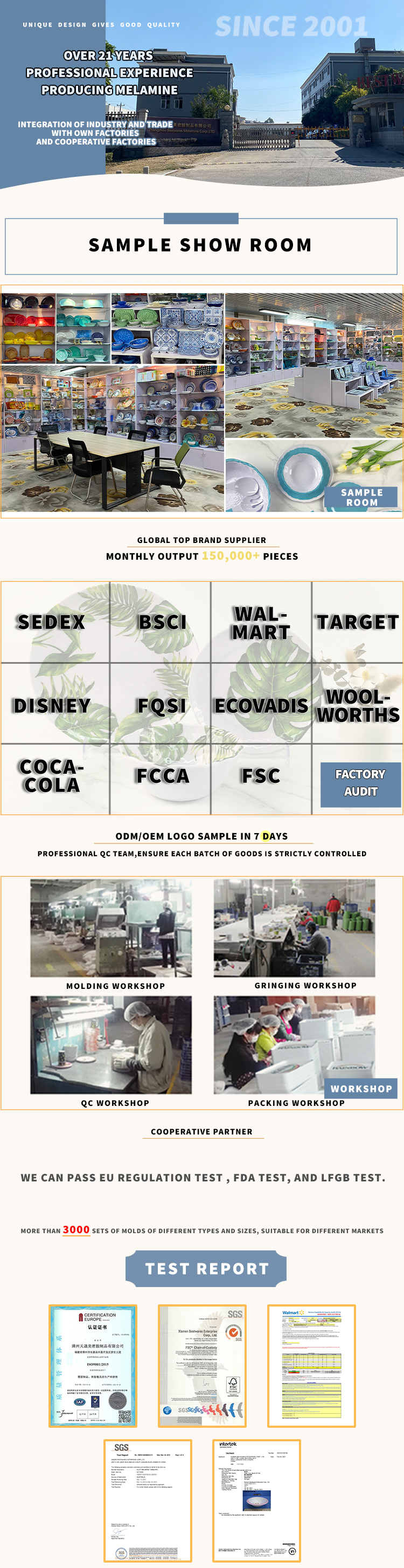

About Us

Post time: Aug-15-2025